- sales@autoamationcontrol.in

- K 10/2, Near PIX TRANSMISSION, M.I.D.C., Hingna, Nagpur

+91 - 702 0901 831

+91 - 702 0901 831

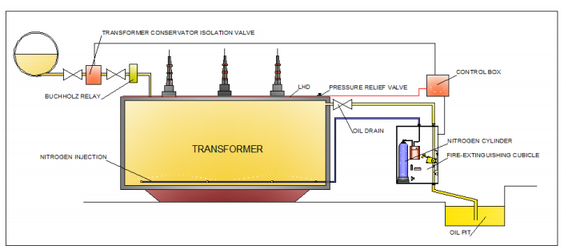

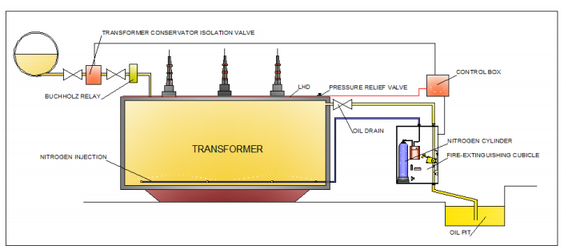

Blast or fire of oil-immersed transformers is generally a result from a breakdown of insulation. It may be caused by over-current, over-voltage, earthing, or short-circuit. If the insulator is decayed and the oil in the transformer is moistened or decomposed, the level of insulation drops. Once it exceeds a limit to cause an electric arc, the oil in the transformer can be decomposed rapidly. Then, many different kinds of ignitable gases are produced and the pressure of the oil tank can easily exceed its limit. As a result, the body of the Transformer or On Load Tap Changer can be broken (or exploded). Consequently, a short circuit take place and cause electric spark. Once the high temperature oil or gas expel out of the transformer and ignite with nature air, fire spreads onto the transformer and the floor. The fire is even worse if the oil continuously delivers to the tank from the oil conservator.

If the transformer is not working properly, an enormous amount of flammable gases is created in the oil tank. As a result, the Bachholz switch closes and the electric breaker switches off. At this moment, the internal pressure of the tank increases due to the thermal inertia. Once the pressure exceeds the setting value of the pressure relief valve (PRV) and the setting value of rupture disk, TEPS 200 is operated immediately. Consequently, the oil drain valve opens to draw off oil in order to relieve the pressure inside the tank and prevent any explosion and fire.

A Unique Activation with Two Principle in one system

1) Rapture Disk, When Transformer oil pressure rises, due to rise in temperature or spark

in the transformer. Rapture disk breakdown automatically at pre-set define pressure. Its

saves the transformer from explosion. As a result, TEPS 200 system is operated and the

oil drains from the rapture disk, to draw off hot oil with gases. Then nitrogen gas is

continuously injected, the large amount nitrogen gas sufficiently cools down the

transformer, extinguishes fire, and prevents any re-combustion.

2) Hammer Type. When the transformer is on fire, the Liner Heat Sensor cable is

activated, the Bachholz switch closes, and the electric breaker switches off. As a result,

TEPS 200 system is operated and the oil drain valve opens to draw off hot oil with

gases. Then nitrogen gas is continuously injected, the large amount nitrogen gas

sufficiently cools down the transformer, extinguishes fire, and prevents any re-

combustion.

State-of-art concept: Activation with Two Principle in one system

1) Rapture Disk 2) Hammer Type. Rapidly drain oil to prevent explosion and inject

nitrogen to prevent and extinct fire.

Excellent performance: utilizing fast valves to drain oil in 0.1 second.

Fast response: once a fault signal is detected from the transformer. The oil is drained

within 0.2 second after detection in order to release pressure and to avoid explosion. The

nitrogen gas is injected after 1 to 20 second in order to mix and cool down the oil, to

reduce the concentration of flammable gases, to isolate oxygen gas, and to extinct fire.

High reliability: Unique two different operating principle that is 1) Rapture Disk 2)

Hammer Type, TEPS-200 utilizing the principle of logic signal to prevent any improper

or unnecessary activity to the system and to provide a more flexible system.

High efficiency: able to inject nitrogen gas continuously for more than 30 min to

completely cool down the transformer oil as well as prevent and extinguish fire.

Reduce pollution: no environmental pollution due to the characteristic of nitrogen gas in

TEPS 200. Extinct fire without water is an advantage to the lack of water area.

Feasibility: easy to install and maintain for both new or existing transformers with

reasonable investment in a minor price compare to other traditional transformer fire

extinction systems, such as water spraying systems and CO2 spraying systems.

Fire extinction medium: 99.99% Nitrogen purity

Nitrogen Cylinder Volume: 40L (1 or 2 Depends on size of transformer)

Nitrogen initial pressure: 150-200 Kg/sq.cm

Oil fast drain valve activation time: <0.2s

Fire extinction time: 1 minute

Nitrogen injection starting time: 3 - 20s (adjustable)

Nitrogen injection time: 31 min (or 45 min with 2 cylinders)

Nitrogen injection pipe diameter: 25 mm

Oil drain pipe diameter: 75 mm or 100 mm

Fire detection : By LHD cable

Depressurized nitrogen: 60 PSI to100 PSI (adjustable)

Operation power supply: DC 220 V - 5A (or DC110V - 10A)

Drying & heating power supply: AC220V 3A, 50Hz

Shutter: Close immediately after draining oil.

Dimensions of fire Extinguishing Cubicle : 1200 X 500 X 1800 (mm)

Control Cabinet can be installed up to 3 Control Box and is located in the substation main control room. Exterior Dimension (length width height): 550 mm X 270 mm X 700 mm Weight: Less than 40 kg.

Each Fire Cabinet protects one transformer installed adjacent to the transformer. Exterior Dimension (length width height): 1200 mm X 500 mm X 1800 mm Weight: 450 kg.

1) Rupture Disk:Rupture Disk is a replaceable emergency pressure relief device actuated by the pre-defined pressure difference between two sides of the disk. Once the pressure in transformer exceeds the pre-set value of the rupture disk, it blasts to allow the oil released from the transformer to the fire cabinet.

2) Fire Detector LHD Cable:A high-strength industrial grade Liner Heat Detector Cable is uses to detect the fire which activated at 1400C ±2 0C. This detector is installed on the top of a transformer where the fire is easily ignited, such as beside a high pressure pie or beside an on load tap changer (OLTC). An electric signal will be sent when fire is detected.

3) Shutter Valve:Shutter valve is installed between the oil conservator and the Bachholz switch and connected by flanges. It operated and close the oil supply when fire is detected by TEPS 200. An electric signal will be delivered to TEPS 200 Control Box if shutter activates.

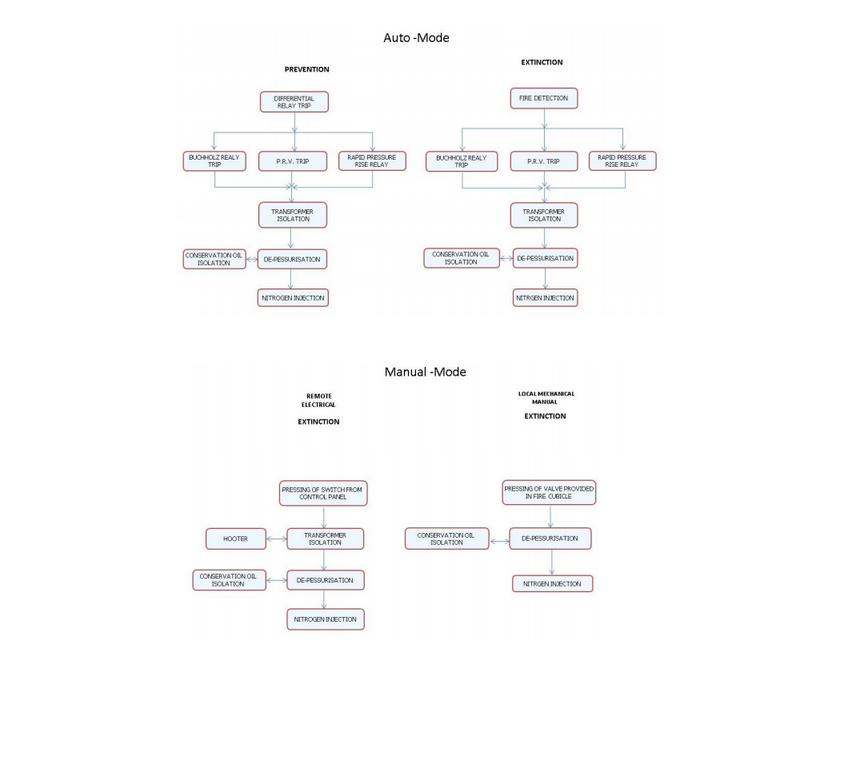

If the transformer is not working properly, an enormous of flammable gases is created in the oil tank. Hence, the Bachholz Relay closes and the electric breaker switches off. At this moment, the internal pressure of transformer increases due to the thermal inertia. Once the pressure exceeds the pre-set value of the rupture disk TEPS 200 system is automatically and instantly operated. Consequently, the drain oil valve opens to draw off oil in order to relieve the pressure inside the tank and prevent any explosion and fire. After draining oil, injected nitrogen through the bottom of transformer body stirs the oil, compulsively cools down failure points and oil temperature, isolates oxygen with a protection layer, cools down the transformer, and prevents any re-combustion.

1. Prevent transformer explosion and fire

2. Extinguish transformer fire

3. Cool down transformer oil

Prevent explosion and fire: Gas Over Concentration + Breaker Tripping + Rupture Disk

Explosion

Extinct fire: Gas Over Concentration + Breaker Tripping + Fire Detector

Activated manually: Breaker Tripping + Activation Condition Switch + Manual Start Up

Confirm Button TEPS 200 Button

"Could not build another home without Sterling! You may think that you don't need it, as I did. Very happy that we proceeded with the complete system. I can't imagine not having it now. Well worth the investment!”

"I am impressed with their dedication and their incredible attention to detail. Also a big thanks to Jim. I just wanted to let you know how well your team performed. They were outstanding in our set up and solving technical glitches. Each of them (Tom/ Mike/Mike and Dennis) were a pleasure to work with.”

“Everyone at Sterling was very professional in all areas. I rate them at the highest level for my overall experience and will recommend them to my friends and colleagues. They have great products and services and I don’t really have any suggestions for how they can improve as they were great in all areas.”